Built on the legacy of Chemtec Energy, Mission Critical delivers high-impact, resilient solutions designed for data center infrastructure.

About Mission Critical

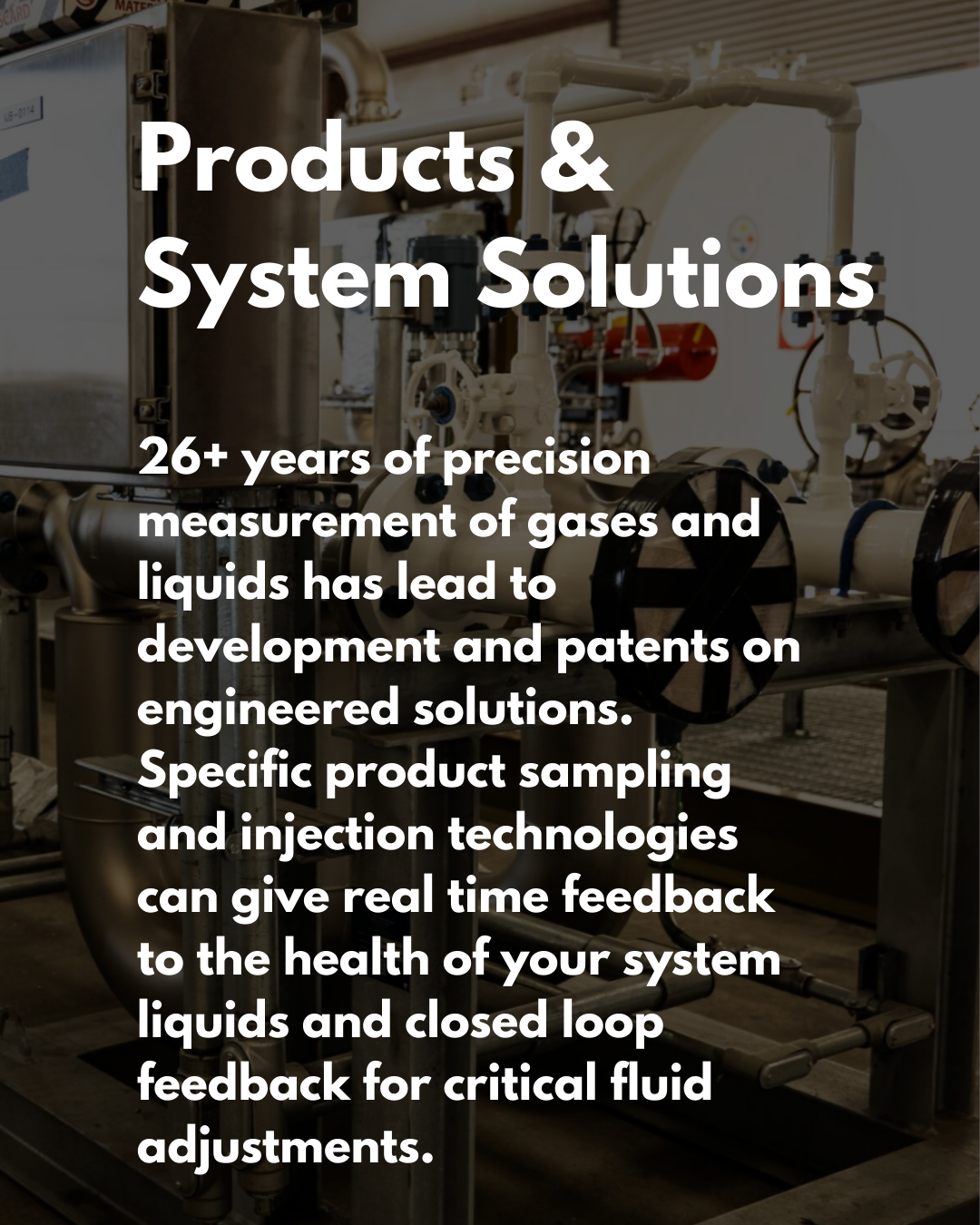

At Chemtec Mission Critical, our mission is to deliver prefabricated, modular turnkey solutions that accelerate data center deployment while enhancing quality and reliability. Through design services, project management, integration, and precision manufacturing, we provide end-to-end infrastructure systems that meet the demands of mission-critical environments where speed, performance, and uptime are non-negotiable.

Our vision is to be the trusted partner in building the backbone of the digital economy—setting the standard for speed, reliability, and innovation in mission-critical infrastructure. By combining decades of high specification fabrication experience with modular execution, we aim to transform how data centers and critical facilities are scaled for the future.

Speed to market is at the core of our modular designs.

By delivering prefabricated solutions that undergo rigorous factory acceptance testing —through level 3 commissioning— we ensure seamless integration and significantly reduce on-site labor requirements. These prefabricated systems not only accelerate lead times, but also enhance quality control and lower overall project costs.

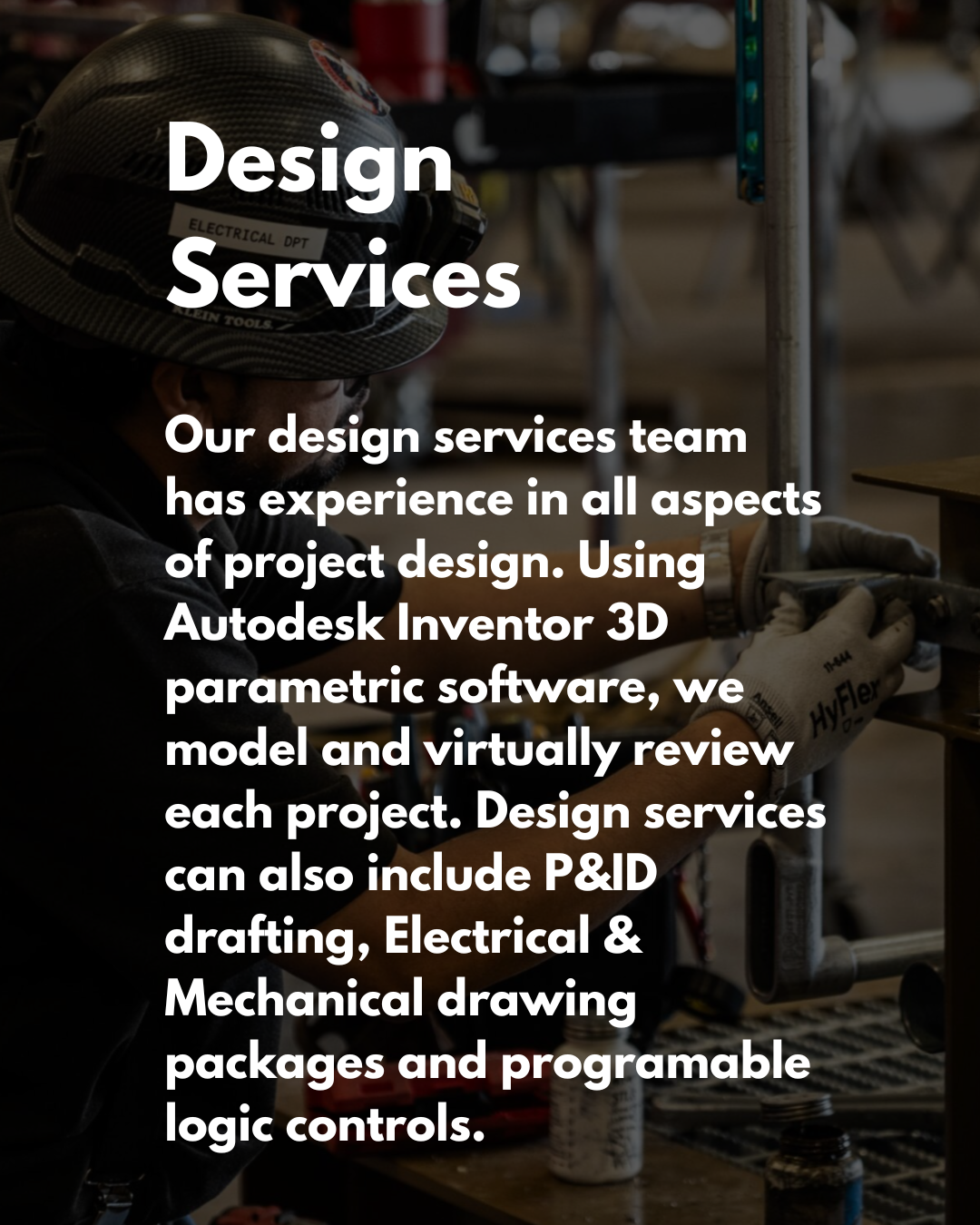

Our in-house team of 3D CAD designers virtually model every solution, testing for safety, fit, form, and operability before fabrication begins. This proactive approach minimizes risks, eliminates costly field modifications, and ensures projects are delivered right the first time.

If You Can't See Your Coolant Chemistry, You Don't Control Your Cooling Loop.

If You Can't See Your Coolant Chemistry, You Don't Control Your Cooling Loop.

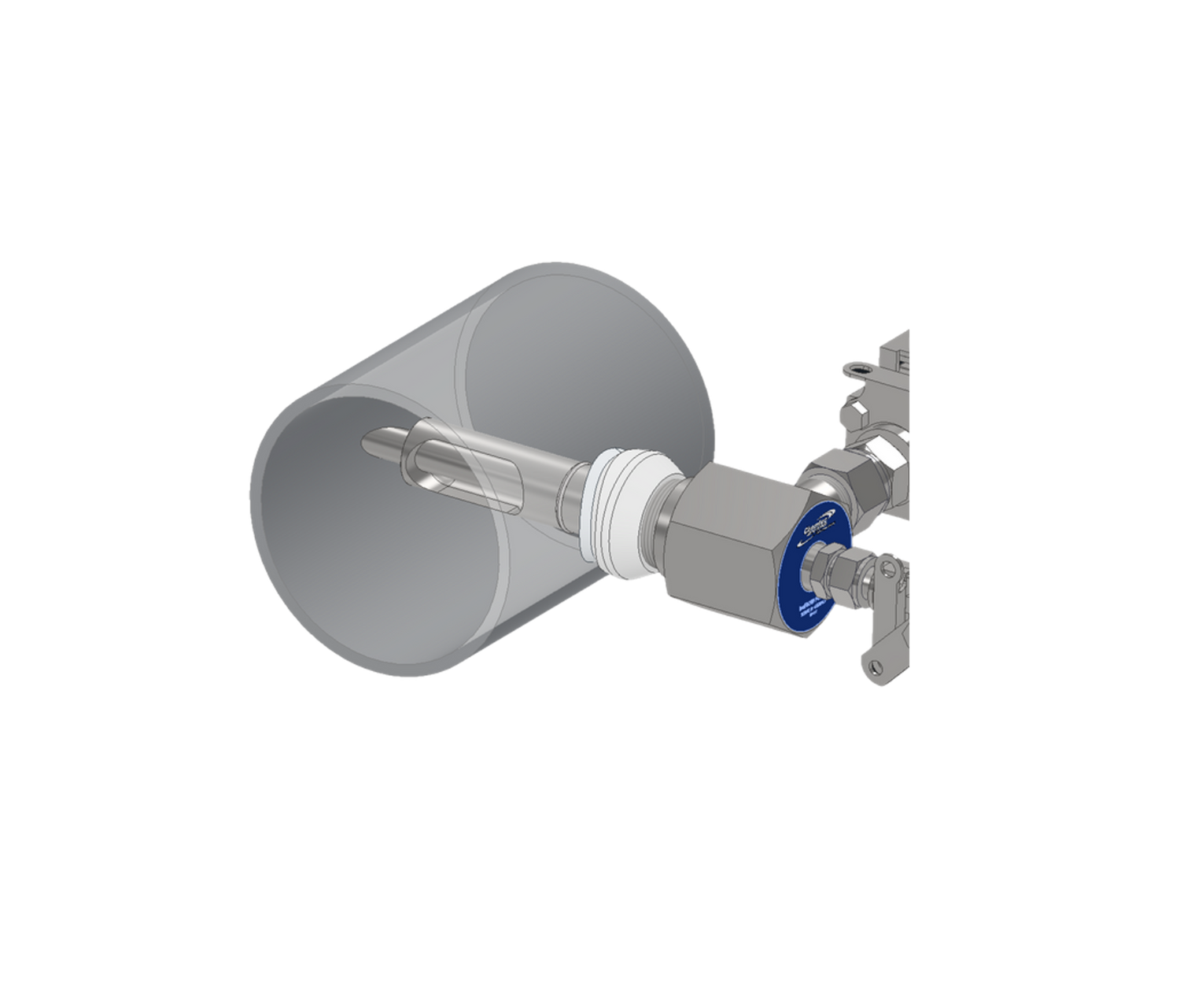

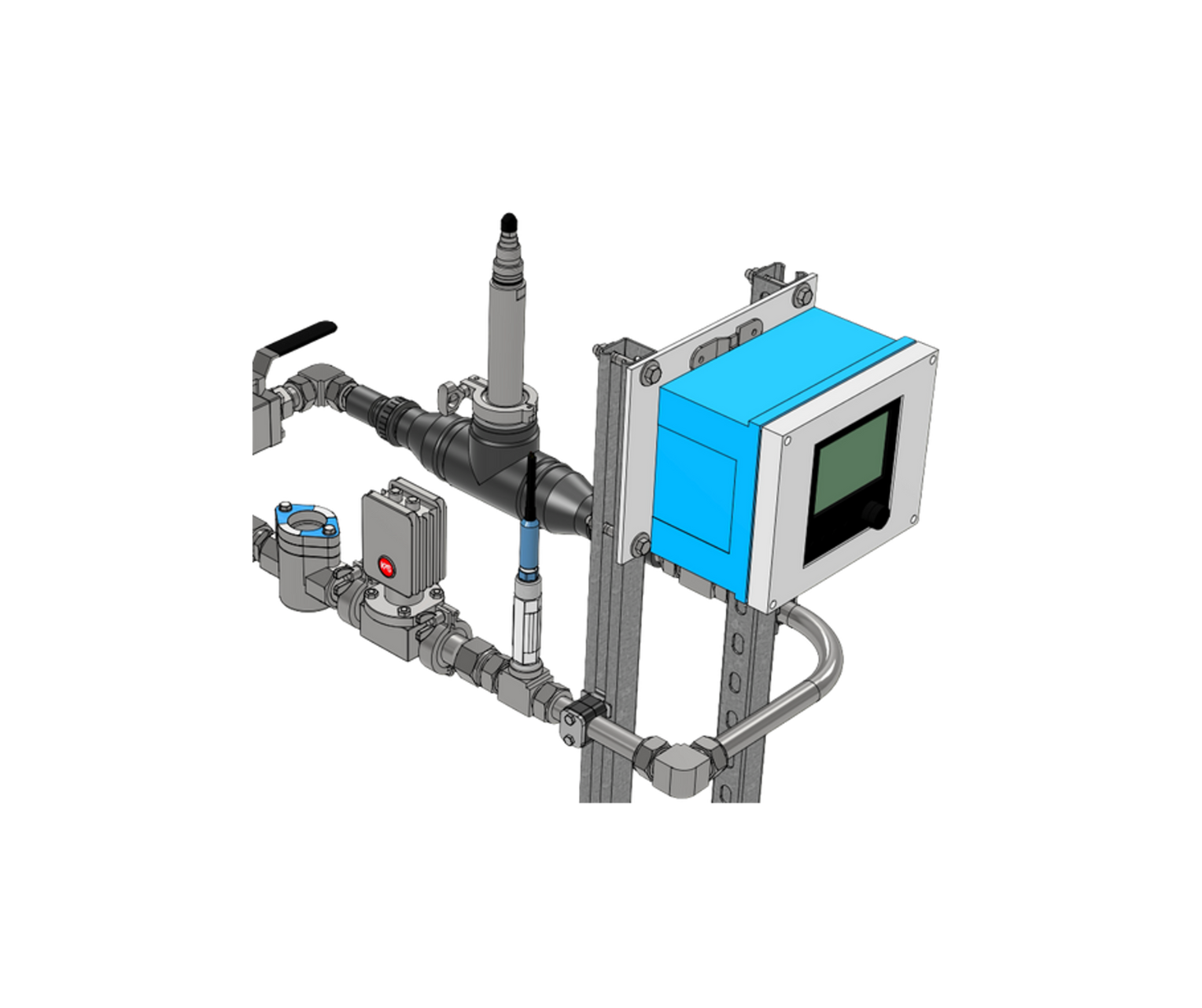

Chemical failure of your coolant fluid begins far before visual detection or traditional measurement resolution.

With the Chemtec Coolant iQ System - real time continuous data is at your fingertips for early detection and root cause management.

Meet the Team

-

Shawn Laughlin

President

-

Andrew Mahon

Vice President

GET MORE INFORMATION

Call or email us with your design needs or vetted design packages. We

will produce budgetary or firm pricing as needed for RFP’s and RFQ’s.

Stay up to date- Follow us on LinkedIn!